Jargon buster

Sustainability and product stewardship jargon buster.

We’ve created a jargon buster with definitions of sustainability and product stewardship terms we get asked about often. If you have more terms you think we should add, we’d love to hear from you.

Definitions for some common terms

-

Circular economy

The circular economy is a model of production and consumption based on three principles. Eliminating waste and pollution, keeping products and materials in use at the highest possible value for as long as possible, and regenerating natural systems. The circular economy is often used in contrast to the linear economy. Read about our work in the circular economy here.

-

Doughnut economics

A concept developed by University of Oxford Economist Kate Raworth, that illustrates sustainable development. It visualises a goal of societal and developmental equity which stays within the limitations of the planet’s natural resources. Where the circular economy focuses on products, doughnut economics focuses on how we share resouces.

-

Downcycling

An outcome where recovered products are turned into other products that are of a lower value, or more difficult to recover and recycle or cannot be recovered and recycled when they reach the end of their life.

-

Duty of care

A concept that assigns responsibility for waste and waste reduction to individuals, households, businesses, and government. A duty of care can be incorporated into regulation or legislation.

-

End-of-life

When a product reaches the end of its useful life and must be recycled, repurposed or otherwise disposed of.

-

EPR or extended producer responsibility

This is another name for product stewardship, used in some places overseas. It’s when all those involved in the supply chain of a product take responsibility for eliminating or reducing the environmental impact of a product throughout its entire life cycle.

-

ESG

ESG stands for environmental, social and governance and is a term often used in association with investment. It is a set of criteria or a lens with which to look at business performance. Many businesses now report on their ESG performance, and many investment funds use it as screening criteria, particularly those funds or products concerned with ethical or sustainable investing.

-

LCA

Life cycle analysis, where the environmental impacts of a product or material are examined and measured throughout its entire life cycle, from resource extraction, use, disposal, through to its end-of-life destination.

-

Mass balance

A term often used in product stewardship, this is the measurement of how much product has been put into the market, versus how much has been recovered, and what happened to it (e.g. recycled, sent to landfill).

-

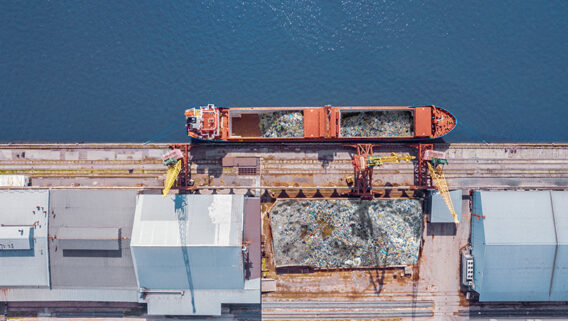

MRF

Materials recovery facility. This is where recovered material is sorted for recycling and other end uses. It can be a commercial operation, one owned by a local council, or run by a not-for-profit or social enterprise group. MRFs make up part of the resource recovery network.

-

Priority product

This is a particular mechanism in New Zealand’s Waste Miminisation Act 2008. The Minister for the Environment can declare a product to be a priority product. When this happens, a product stewardship scheme must be formed for that product with mandatory participation by producers and members of the supply chain.

-

Product stewardship or producer responsibility

When producers, brand owners, retailers and consumers all play their part in taking responsibility for eliminating or reducing the environmental impact of a product throughout its life cycle. In some places this is known as EPR or extended producer responsibility. Read more about product stewardship.

-

Product stewardship scheme

A product stewardship scheme is a system that is designed to manage products throughout their entire lifecycle to reduce or eliminate their environmental impact. It usually involves members of an entire industry or supply chain. It is governed by a product stewardship organisation (PSO). The operational aspects of the scheme may be carried out by the PSO, or by an appointed scheme manager, or a mixture of both.

-

PSO

Product stewardship organisation. This is the name for the governance body that oversees a product stewardship scheme. Best practice is that the makeup of a product stewardship organisation should reflect the range of stakeholders a scheme has.

-

Resource recovery network

The resource recovery network is made up of businesses and organisations that help divert waste from landfill so that it can be reused, repaired or recycled. It includes local government, waste contractors, not-for-profit organisations, social enterprises.

-

Recovery rate

The percentage of a material or product that is diverted from landfill at the end of its life for reuse and recycling. In some cases not all of the recovered material is able to be recycled. For example it may be made up of several components, some of which can be recycled and some of which can’t. Or some recovered material may be too contaminated to recycle.

-

Recycling rate

The percentage of material that is diverted from landfill and recycled. This can be measured against the total amount of material to market, and against the amount of material recovered. This tells us how well we are doing at diverting material, as well as how much of that material is able to be recycled.

-

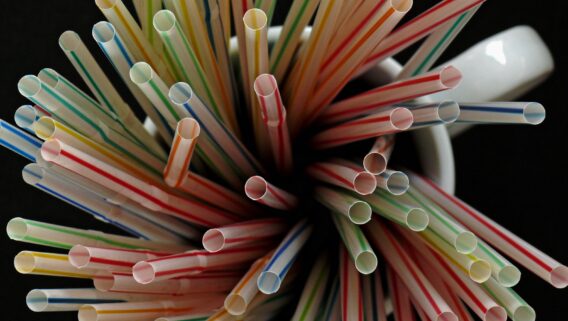

Regulated product stewardship

Regulated product stewardship is also sometimes called mandatory product stewardship. This is where government uses legislative or regulatory mechanisms to ensure producers participate in product stewardship schemes that eliminate or minimise environmental harm from their products. This is also known in some places as EPR or Extended Producer Responsibility.

-

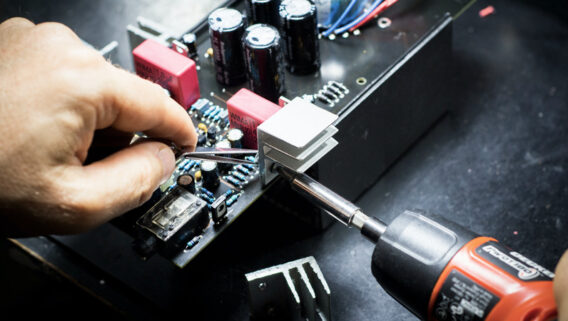

Right to repair

The concept that products should be manufactured and managed to make them easy and economical to repair, rather than thrown away. For example, manufacturers making parts available at reasonable cost. In some places around the world this is becoming regulated.

-

Scheme manager (product stewardship)

An organisation that carries out the operational aspects of a product stewardship scheme on behalf of the product stewardship organisation.

-

SDGs

The United Nations Sustainable Development Goals. A framework that countries, businesses and organisations can use to align their goals for a more economically, environmentally and socially sustainable world. You can find 3R’s reporting about our sustainable development goals on our sustainability page.

-

Takeback (or take back) scheme

This is where businesses or industries take back their own product and/or packaging to divert it from landfill and manage its end-of-life. These schemes do not usually impact on the whole product life cycle.

-

Voluntary product stewardship

Voluntary product stewardship is when industry decides to create and take part in a product stewardship system without being compelled to by government regulation or legislation. Best practice voluntary schemes have many of the same aims and characteristics of regulated or mandatory product stewardship.

-

Waste advisory board

An independent board that provides advice to the Minister for the Environment about waste minimisation issues.

-

Waste hierarchy

The waste hierarchy sets out the ways of dealing with waste, from the most desirable to the least desirable. The steps in the hierarchy from most to least desirable are prevent (or avoid), reduce, reuse, recycle, recover and dispose.

-

Waste strategy (national)

A strategy set by government that helps to inform legislation, regulation and policy about waste.

-

Waste to energy

Systems that convert any waste to energy. This can include processes such as incineration, biodigestion or pyrolisation of waste to create energy for a local or national grid, or as alternative fuels.

-

WMA 2008

New Zealand’s current waste legislation, the Waste Minimisation Act 2008. This is currently under review.

-

WMF

The government’s Waste Minimisation Fund. It awards funds to organisations for initiatives that reduce waste, or boost recycling and other end-of-life solutions.